Ductwork Between Floor Joists: One Easy Ways to Installation

Ductwork is a key part of modern HVAC systems. It helps air flow well and keeps indoor spaces comfortable. One smart way to install ductwork is between floor joists. This method saves space and improves efficiency, looks, and home value.

In this blog, you’ll learn all about installing ductwork between floor joists. We’ll explain the benefits, walk you through the steps, and share helpful tips to make the job easier. Boost your home’s HVAC system and discover how this setup can add comfort and value to your space.

What Is Ductwork Between Floor Joists?

Ductwork installation between floor joists is a smart way to run air ducts in homes and small buildings. This method uses the space between wooden beams to save room in walls, ceilings, and floors.

It keeps the building looking neat while providing good airflow. These under-floor duct systems fit right into the structure, sending air where needed without taking up living space. They are a simple and effective solution for moving air.

These systems work well in homes and small businesses. They are easy to install and maintain. These ducts preserve the building’s design by blending function with style. They also make homes and workplaces more comfortable for everyone.

Benefits of Installing Ductwork Between Floor Joists

There are numerous benefits to using floor joist spaces for ductwork. Here’s a closer look:

Space-Saving Design

Maximizing space between floor joists is an intelligent strategy for increasing square footage without disrupting living areas. This innovative method allows homeowners and builders to optimize space, turning unused areas into functional storage or utility spaces.

It’s particularly advantageous for compact homes and buildings where every inch matters. This approach enhances organization and efficiency without significant renovations, making homes more spacious and comfortable.

By creatively using this technique, residents can enjoy a well-organized living environment. Keywords: maximize space, floor joists, compact homes, storage solutions, home organization.

Improved Air Distribution

Adequately installed ductwork is essential for maintaining consistent air circulation throughout your home, ensuring every room remains comfortable. Correct installation prevents “hot” or “cold” spots caused by uneven air distribution.

This improves home comfort and energy efficiency, as your heating and cooling systems can work less hard to maintain ideal temperatures.

Enjoy a consistently pleasant home atmosphere while potentially lowering your energy bills. Invest in professional duct installation for a more energy-efficient and comfortable home.

Enhanced Energy Efficiency

Properly installed and insulated ducts between floor joists are vital for preventing home energy loss. By maintaining consistent air pressure and temperature, these ducts ensure efficient heating and cooling.

This consistency reduces energy consumption and enhances comfort by delivering steady climate control. Additionally, well-insulated ducts can lower utility bills and reduce the environmental impact of energy usage. For optimal home energy efficiency, prioritize duct insulation and installation.

Protection from External Damage

Duct systems encased within the floor structure benefit from natural protection against physical damage and harsh weather conditions, such as rain, wind, and temperature changes.

This strategic positioning enhances the longevity of HVAC ductwork and boosts the efficiency of the entire HVAC system.

Consistent airflow reduces the chances of leaks and obstructions. Well-protected duct systems are essential for optimal HVAC performance and energy efficiency.

Noise Reduction

This setup effectively reduces HVAC noise by using specialized design features. Our structure is crafted with sound-absorbing materials that minimize noise from air systems.

This HVAC noise reduction approach boosts acoustical comfort and creates a quieter, more productive atmosphere for occupants. Improve your environment with our innovative noise control solutions today!

Improved Aesthetic Integration into Home Design

Integrating ductwork beneath the floor offers a modern solution to eliminating unsightly vents and protruding pipes. This approach enhances a space’s sleek design and seamlessly integrates heating and cooling systems.

By choosing underfloor ductwork, you can maintain uninterrupted decor, boost aesthetic appeal, and create a clean, streamlined environment.

This method aligns perfectly with contemporary architectural trends and maximizes the room’s overall feel. Embrace this innovative setup to enhance your home’s design and comfort.

Increased Home Resale Value

Today’s home buyers highly value energy-efficient and space-saving homes. There is a need to cut energy costs and optimize living space. Fuels this trend

Homes with underfloor duct systems are especially appealing, as they efficiently manage heating and cooling while saving space. These energy-efficient systems improve home comfort and promote a sustainable lifestyle, making them wise for future homeowners.

Underfloor duct systems are crucial for homes with sustainable features and energy efficiency.

Types of Ducts Suitable for Installation Between Floor Joists

Choosing the correct type of duct is critical when working within tight spaces like floor joists. Below are the most suitable options:

1. Flexible Ducts

Flexible ducts are popular in HVAC systems because they are lightweight and easy to handle. They are ideal for navigating compact and curved pathways and tight spaces.

They feature a core, insulation, and outer jacket, simplifying installation and enhancing versatility. The insulation layer reduces heat loss or gain, modestly improving air travel efficiency.

Although not as efficient as rigid ducts, flexible ducts offer adaptability and convenience, making them a top choice in many HVAC applications—keywords: flexible ducts, HVAC systems, easy installation, thermal efficiency, adaptable ducts.

2. Rigid Ducts

Rigid ducts, available in aluminum or galvanized steel, are perfect for durable, long-term installations in residential, commercial, and industrial environments.

These sturdy ducts provide high static pressure, promoting efficient airflow and excellent resistance to leakage. This ensures optimal performance and energy efficiency over time.

Their robust construction minimizes damage during installation and use, making them a reliable choice for HVAC systems. Choose rigid ducts for their durability, efficiency, and performance in any setting.

3. Semi-Rigid Ducts

These flexible and durable ducts are ideal for many applications, thanks to their construction from high-quality materials.

They offer easy bending and maneuverability while maintaining a sturdy structure that withstands wear and tear. Perfect for applications needing moderate airflow adjustments, these ducts can be tailored to specific needs without losing integrity.

Their versatility makes them suitable for both residential and commercial use. Ideal for HVAC systems, ductwork installation, and airflow optimization, these adaptable ducts ensure reliable performance in various settings.

4. Oval Ducts

Oval ducts are perfect for tight spaces. They offer efficiency comparable to circular ducts, but with a snug fit between floor joists. These ducts are ideal for areas with limited room, ensure optimal airflow, and maintain a low profile.

Engineered for high performance, oval ducts don’t compromise space utilization. They offer an effective ventilation solution for residential or commercial use in constrained environments.

With keywords like “efficient HVAC,” “space-saving ductwork,” and “optimal airflow design,” oval ducts are a practical choice for maximizing ventilation.

5. Insulated Ducts

Pre-insulated ducts are crucial in modern HVAC systems that boost energy efficiency by minimizing heat transfer through duct walls.

Equipped with insulation, these ducts ensure air remains at the desired temperature, reducing energy loss. Optimize your HVAC system, and consider incorporating pre-insulated ducts to save energy and improve system longevity.

6. Pre-Insulated Spiral Ducts for Energy Efficiency

These energy-efficient HVAC ducts offer a perfect blend of durability and performance, making them a top choice for high-performance heating and cooling systems.

With their robust construction, these ducts ensure long-lasting reliability, help lower operational costs, and reduce environmental impact. Ideal for residential and commercial applications, these high-efficiency HVAC ducts prioritize efficiency and reliability, making them a wise investment for any property.

Essential Materials and Tools for Ductwork Installation

Successful ductwork installation requires the following tools and materials:

Tools

- Measuring Tools: Essential tools like measuring tape and laser measures are crucial for obtaining accurate dimensions and ensuring perfect fits during installation.

- Cutting Tools for Ducts and Wood: Tools such as tin snips and saws are necessary for trimming and fitting ducts and wood components to desired lengths and shapes.

- Duct Sealing Materials: Duct tape and sealing materials are vital for securing duct connections and preventing air leaks, which maintain HVAC system efficiency.

- Insulation Material: Insulation is crucial for temperature control and energy efficiency, reducing heat loss or gain in duct systems.

- Support Brackets and Mounting Connectors: These provide stability and secure installations, keeping ducts and other components firmly in place.

- Protective Gear: Safety equipment like goggles and gloves are essential for personal protection during cutting and installation.

Optimize your HVAC installation with these tools and materials for improved performance and safety.

Materials

- Duct Type Selection (Flexible, Rigid, etc.): Consider space constraints and airflow needs when choosing the right duct type for your application. Keywords: duct type, flexible duct, rigid duct.

- Duct Connectors and End Caps: Ensure secure connections with appropriate duct connectors and use end caps to seal open ends for optimal airflow—keywords: duct connectors, end caps.

- Airtight Duct Sealing (Sealants or Mastic): Use quality sealants or mastic for airtight duct connections to prevent leaks and enhance system efficiency—keywords: airtight duct sealing, duct sealants, mastic.

- Anti-Vibration Pads for Ducts: Install anti-vibration pads to reduce noise and vibration, improving duct system comfort and longevity—keywords: anti-vibration pads, duct noise reduction.

How to Run Ductwork Between Floor Joists: Step-by-Step Installation Guide

Assessing Feasibility and Suitability

Thoroughly evaluate your property’s structure by inspecting the existing floor joists to ensure they can support ductwork without compromising the building’s integrity.

Check the load-bearing capacity of the joists and determine if reinforcements are needed to handle extra weight and modifications. Proper structural evaluation can prevent potential issues and ensure long-term stability.

Keywords include property structure, floor joists, building integrity, load-bearing capacity, ductwork, and structural assessment.

Planning and Design Considerations

- Optimize building airflow by mapping routes and identifying obstacles to improve ventilation efficiency. Assess the layout to ensure optimal air circulation.

- Leverage HVAC planning software like AutoCAD to create detailed schematics and simulations. This ensures precise installation and enhances system performance for adequate heating, ventilation, and air conditioning.

Gathering Necessary Permits and Approvals

Thoroughly review all regulations and guidelines to ensure compliance with local building codes. Before starting your construction project, submit applications and documentation to the relevant authorities to secure necessary permits.

By understanding local building laws and securing permits early, you can stay compliant, avoid delays, and ensure a smooth building process.

Removing Existing Obstacles

Remove debris, furniture, and outdated ductwork to keep designated pathways clear of obstructions, enhancing safety and efficiency.

Regularly checking these pathways helps prevent hazards and ensures optimal movement conditions. Maintaining clear and safe paths contributes to a safer, more efficient environment.

Marking Out and Measuring Duct Pathways

Accurate measurements are essential for reducing errors during installation. Proper measurements ensure a smooth execution, minimizing the need for adjustments.

Using precise measurement techniques guarantees the perfect fitment, saving time and resources while improving the quality and longevity of the installation.

Installers can achieve optimal results and avoid complications by carefully measuring and double-checking dimensions. Prioritize accurate measurements for successful installations and superior outcomes.

Cutting and Fitting Ducts

To install ductwork effectively, cut the ducts to the necessary length with tin snips or similar cutting tools. This ensures clean and precise cuts. Once cut, fit the ducts securely into their designated spaces.

Double-check they are aligned correctly and positioned snugly to ensure optimal airflow and HVAC performance. Using proper duct installation techniques helps maximize energy efficiency in HVAC systems.

Securing Ducts in Place

Securely attach air ducts to joists using strong brackets, ensuring proper alignment to maintain efficient airflow. Firmly securing the ducts prevents sagging or displacement, which could otherwise affect system performance.

Check all connections to ensure they are tight and reliable, providing a well-functioning HVAC duct system—keywords: air ducts, HVAC, airflow, system performance, duct installation.

Sealing Joints and Connections

Apply sealants carefully to all joints to improve energy efficiency and prevent air or water leaks. This helps maintain a consistent indoor climate and reduces heating and cooling costs.

By minimizing energy waste, you contribute to a more sustainable environment. Seal joints properly to ensure your home or building is energy-efficient, leading to lower utility bills and a greener footprint.

Testing for Airflow and Leaks

Inspecting airflow in your ventilation system is crucial for ensuring efficiency. Use pressure gauges or smoke tests to evaluate air circulation.

Carefully observe the results to detect any blockages or irregularities. If you notice discrepancies, adjust accordingly to optimize airflow and maintain peak system performance.

Regular ventilation system maintenance can significantly improve indoor air quality and energy efficiency.

Common Challenges and How to Overcome Them

Limited Space Between Joists

If the space between joists is too narrow, consider using rectangular ducts with smaller dimensions. These are ideal for tight spaces and maintain efficient airflow. Rectangular ducts are a practical solution for ensuring adequate ventilation in areas with structural limitations.

Alternatively, round or oval-shaped ducts can fit into tighter spaces, providing optimal air distribution. These duct shapes allow for easier installation and superior aerodynamic performance, making them versatile for architectural designs. Choose ductwork that ensures efficient ventilation and airflow in any space for the best results.

Sagging Flexible Ducts

Flexible ducts often sag because of their weight and lack of structural support, which can restrict airflow. This restriction leads to decreased HVAC efficiency and higher energy costs.

To maintain optimal system performance, it’s crucial to regularly prevent sagging using supports like hangers or metal straps. Avoid installing long stretches of unsupported flexible ductwork to reduce the risk of damage and ensure efficient airflow.

Navigating Obstacles

Installing HVAC ductwork often involves precisely cutting and shaping the ducts and navigating obstacles such as plumbing, electrical wiring, or structural components.

To tackle these challenges effectively, use essential tools like cutting snips and hand crimpers to cut and shape the ducts precisely. Consider incorporating adjustable elbows or flexible joints to maneuver around obstacles quickly.

Planning carefully and selecting suitable materials, you can confidently overcome obstructions during HVAC duct installation.

Keywords to focus on for this process include “HVAC ductwork installation,” “overcome obstacles,” “cutting snips,” “hand crimpers,” “adjustable elbows,” and “flexible joints.” to maneuver around obstacles easily.

Maintaining Proper Airflow

Maintaining optimal airflow is a significant challenge in HVAC duct installation. Common issues, such as improperly connected ducts, incorrect sizing, and obstructions, can disrupt airflow.

To ensure efficient HVAC performance, regularly inspect and maintain your ductwork. Check for leaks, blockages, and damage that could hinder airflow. Secure all connections and seal them properly to prevent air loss.

By closely monitoring your HVAC system’s performance and addressing issues early, you can ensure proper airflow and enhance energy efficiency. Prioritize regular duct maintenance to keep your HVAC system running smoothly.

Ensuring Adequate Insulation

Proper insulation is critical to maximizing HVAC efficiency and reducing energy costs. You might experience temperature fluctuations, leaks, and poor indoor air quality without adequate insulation.

When installing ductwork, ensure it’s insulated with fiberglass or foam board to enhance energy efficiency. Properly sealing and insulating your ducts helps maintain consistent indoor temperatures and prevents energy loss. Optimize your HVAC system today for better performance and lower energy bills!

Air Leaks at Connections

One of the biggest challenges in HVAC duct installation is preventing air leaks at connections. Air duct leaks can dramatically decrease HVAC system efficiency and increase energy costs.

To avoid this common issue, use high-quality HVAC sealants or duct tape designed for ductwork. Ensure all duct connections are tight and properly sealed to prevent air loss.

Regularly inspect your air ducts for signs of wear or damage that could cause air leaks. By addressing these HVAC issues promptly, you can maintain optimal airflow and improve HVAC performance.

Preventing Mold or Mildew in Ducts

Mold and mildew thrive in warm, humid environments, making your ventilation system a prime breeding ground. These contaminants harm indoor air quality and damage ductwork.

To prevent mold and mildew growth in your HVAC system, ensure proper insulation and ventilation to keep moisture levels low. Regularly clean and maintain your HVAC system to minimize the risk of mold or mildew buildup.

Consider installing UV lights in your ductwork to destroy bacteria and mold spores. By taking these proactive steps, you can improve indoor air quality and extend the life of your HVAC system.

Prioritizing Safety During Installation

Protective Gear Recommendations

When working with HVAC ductwork, safety should be your top priority. WT High protective gear is crucial to prevent injuries and ensure a safe work environment. Essential safety equipment for HVAC ductwork includes:

- Gloves for HVAC work: These protect your hands from cuts and scrapes when handling sharp tools or materials like sheet metal.

- HVAC technicians must wear safety glasses to shield their eyes from flying debris or particles during duct cutting or shaping.

- Dust mask for HVAC installation: A dust mask helps reduce the risk of inhaling dust, insulation fibers, and other harmful particles.

- Knee pads for HVAC installation: Knee pads provide cushioning and support, making kneeling or crawling during installation more comfortable.

- Hard hat for HVAC construction: A hard hat is vital in areas with a risk of falling objects.

Wearing the appropriate HVAC safety gear can significantly reduce the risk of injuries and maintain a secure working environment.

Compliance with Building Codes

Building codes and regulations are paramount in HVAC duct installation. These standards ensure safety and efficiency throughout the construction process.

Before commencing any work, you must familiarize yourself with local and national building codes related to HVAC systems. If you have any questions or concerns about compliance, consult a licensed professional or regional authorities.

Enhancing Energy Efficiency Through Proper Ductwork Installation

Proper ductwork installation is essential for boosting energy efficiency and reducing energy costs. You can enhance your HVAC system’s performance by ensuring adequate insulation, sealing air leaks, and prioritizing safety during installation.

Regular maintenance and ductwork cleaning improve indoor air quality and extend the lifespan of your HVAC system. Adhering to building codes and using protective gear during HVAC installations ensures a safe project.

Following these guidelines can increase energy efficiency in your home or building. Regular duct maintenance is critical to running your HVAC system smoothly and efficiently. Use these tips to achieve optimal performance from your HVAC system and enjoy lower energy bills and better air quality.

Mistakes to Avoid During Ductwork Installation

Skipping the Planning Stage

Proper planning is essential for a successful ductwork installation. Skipping this crucial step can lead to costly mistakes, delays, and increased expenses.

Before starting the duct installation process, evaluate your building’s layout and identify the optimal routes. Effective HVAC planning and design can save time and money while ensuring efficient airflow.

Using Incorrect Duct Sizes

Choosing the correct duct size is crucial for optimal HVAC system performance. Oversized ducts can lead to rapid airflow, which increases energy use and lowers efficiency.

Conversely, undersized ducts may limit airflow and strain your HVAC system. To ensure efficient heating and cooling, consult an HVAC professional to select suitable duct sizes tailored to your needs. Proper HVAC duct sizing is critical to energy efficiency and system longevity.

The Cost of Installing Ductwork Between Floor Joists

DIY vs. professional installation cost breakdown.

The cost of installing ductwork between floor joists can vary depending on whether you choose to do it yourself or hire a professional HVAC contractor.

DIY installation may seem more budget-friendly, but it’s essential to consider the potential risks and complications arising from incorrect installation. In contrast, hiring a licensed professional ensures proper installation and adherence to building codes.

DIY Ductwork Installation:

Material Costs: Materials for DIY ductwork installation can range from $1,000 to $3,500.

Time and Labor: It can take four days for an experienced DIYer to complete the installation process. If any mistakes are made during

Long-term energy savings as an ROI.

Although professional ductwork installation may have a higher initial cost, it offers long-term energy savings and a superior return on investment (ROI).

Well-installed ductwork ensures efficient air distribution, minimizing energy waste and reducing monthly utility bills. Moreover, professional installations usually include warranties that cover potential issues, offering peace of mind and possible savings on future repairs.

Maintenance Tips

- Regular Duct Cleaning: Schedule professional air duct cleaning every few years to prevent the buildup of dust and debris in your HVAC system. Regular maintenance helps improve indoor air quality and improves system efficiency.

- Duct Damage Inspection: Conduct routine inspections of your air ducts for any signs of damage, such as leaks, tears, or crushed sections. By identifying and repairing these duct issues early, you can boost the performance of your heating and cooling system and extend its lifespan.

- Airflow Monitoring: To ensure proper airflow throughout your home, keep all vents and grilles free from obstructions like furniture or curtains. Consistent airflow is vital for even temperature distribution and optimal HVAC system efficiency.

Frequently Asked Questions (FAQs)

The 2-foot rule for ducts refers to the minimum distance between a duct and any object above or below it. This rule ensures enough space for proper insulation, efficient airflow, and safe installation.

Yes, you can install ductwork between floor joists as long as building codes are followed and proper planning is done to ensure efficiency and safety. Consult with an HVAC professional for guidance on the optimal placement of ducts in your specific building structure.

Signs that your ductwork may need cleaning include higher-than-usual energy bills, visible dirt and dust buildup on vents, and musty or unpleasant odors from your HVAC system. It's recommended your ducts be professionally cleaned every 3-5 years.

Blocking between floor joists, also called bridging or cross-bridging, helps distribute weight and prevent floor sagging. It reduces noise transmission between floors and adds rigidity to a building. Proper blocking placement and spacing are crucial for structural integrity and safety, especially for ductwork installation. Consult building codes and professionals for guidance on using blocking in your construction project.

End of content related to general topics discussed throughout the content - continue writing additional educational information related to HVAC systems:

Accessing ductwork between floors can be challenging, but it's possible through access panels or ceiling registers. Access panels are typically installed during construction and allow easy maintenance and repairs to the ductwork. If there are no access panels, a professional HVAC contractor may need to create one by cutting into the ceiling or using specialized tools to reach the ducts.

Insulating ductwork between floor joists is highly recommended for improved energy efficiency and noise reduction. Uninsulated ducts can lose up to 25% of heated or cooled air due to temperature differences in unconditioned spaces like attics or basements. Insulation helps maintain consistent temperatures and reduces the workload on your HVAC system, resulting in energy savings and lower utility bills.

the blind texts. Separated they live in Bookmarksgrove right at the coast

Relocating ductwork between floor joists can be complex and costly, as it often requires your home's structure modifications. Before attempting to relocate any ductwork, consult with a professional HVAC contractor. They can assess your situation and guide you on the best approach for safely relocating ducts.

Wood can touch ductwork, but proper installation requires following building codes and safety guidelines. Wood framing should be at least 1 inch from the duct's exterior, and any wood touching the duct must have a fire-retardant coating. Consult professionals for guidance on safely installing wood near ductwork.

In conclusion, proper planning, installation, and maintenance are necessary for efficient and safe ductwork between floor joists. By adhering to building codes, hiring professionals when needed, and conducting routine inspections and cleaning, you can maximize energy savings and ensure optimal HVAC performance.

Conclusion

Installing ductwork between floor joists is a common and practical solution for efficiently distributing heated or cooled air in buildings. It requires careful planning and proper installation following building codes to ensure safety and efficiency.

Routine maintenance, such as regular duct cleaning, inspections, and monitoring airflow, can further enhance the performance of your HVAC system and provide long-term energy savings. Remember to consult with professionals for guidance on any specific issues or concerns related to ductwork between floor joists in your building project.

So, confidently tackle your next DIY project, knowing the importance of properly installing and maintaining ductwork between floor joists.

Related Posts

-

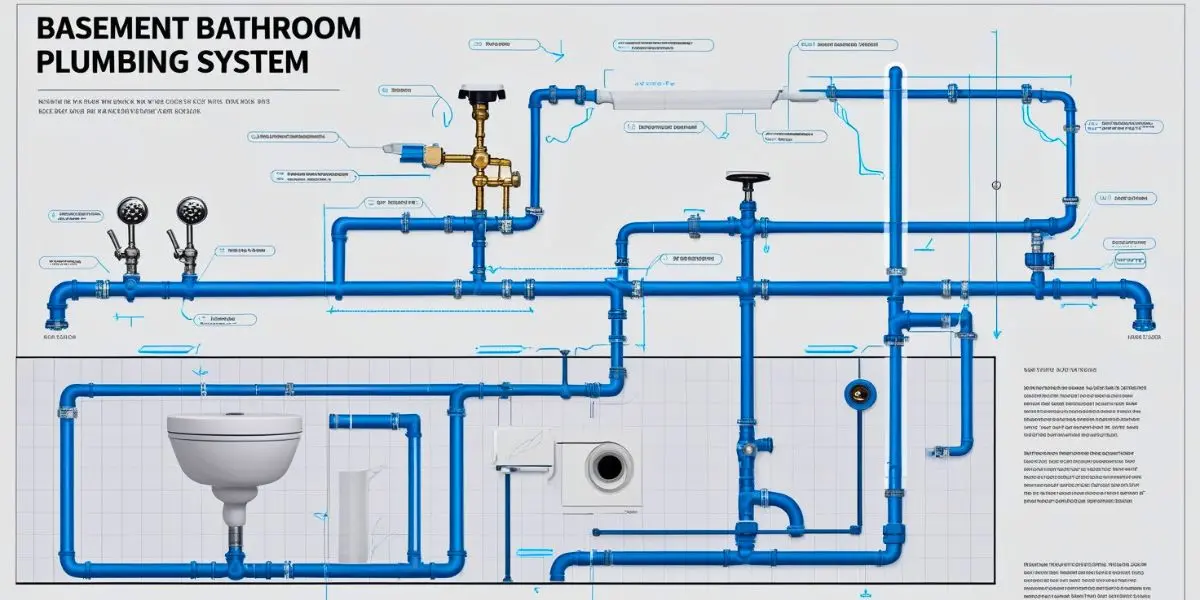

Simple & Effective: Basement Bathroom Plumbing Diagram

Simple & Effective: Basement Bathroom Plumbing Diagram -

Can I Change the Shower Head in My Apartment? A Quick Guide

Can I Change the Shower Head in My Apartment? A Quick Guide -

How to Fix Kitchen Drawers That Fall Off Track: Unlimited Guide

How to Fix Kitchen Drawers That Fall Off Track: Unlimited Guide -

How to Raise a Shower Floor: Essential Tips

How to Raise a Shower Floor: Essential Tips -

70s Kitchen Remodel Before and After Expert Tips

70s Kitchen Remodel Before and After Expert Tips -

The Ultimate Guide to a Raised Bathroom on a Concrete Slab

The Ultimate Guide to a Raised Bathroom on a Concrete Slab -

Average Kitchen Remodel Cost: Unlimited Tips

Average Kitchen Remodel Cost: Unlimited Tips -

Running Romex Through Floor Joists: A Comprehensive Guide

Running Romex Through Floor Joists: A Comprehensive Guide -

Ductwork Between Floor Joists: One Easy Ways to Installation

Ductwork Between Floor Joists: One Easy Ways to Installation -

Floating Floor Meets Exterior Door Threshold: Expert Tips

Floating Floor Meets Exterior Door Threshold: Expert Tips